Flexibility of our Plating Service

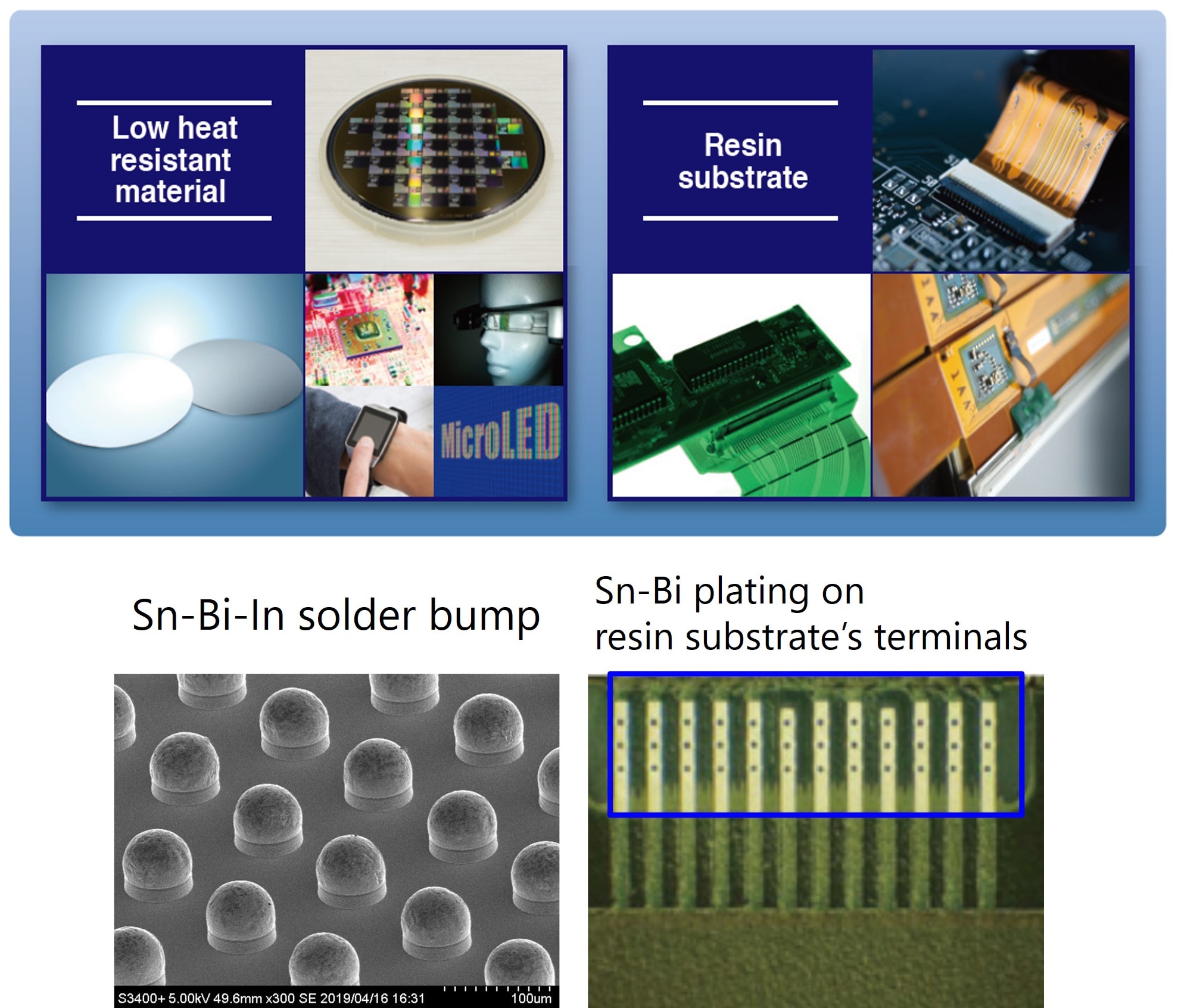

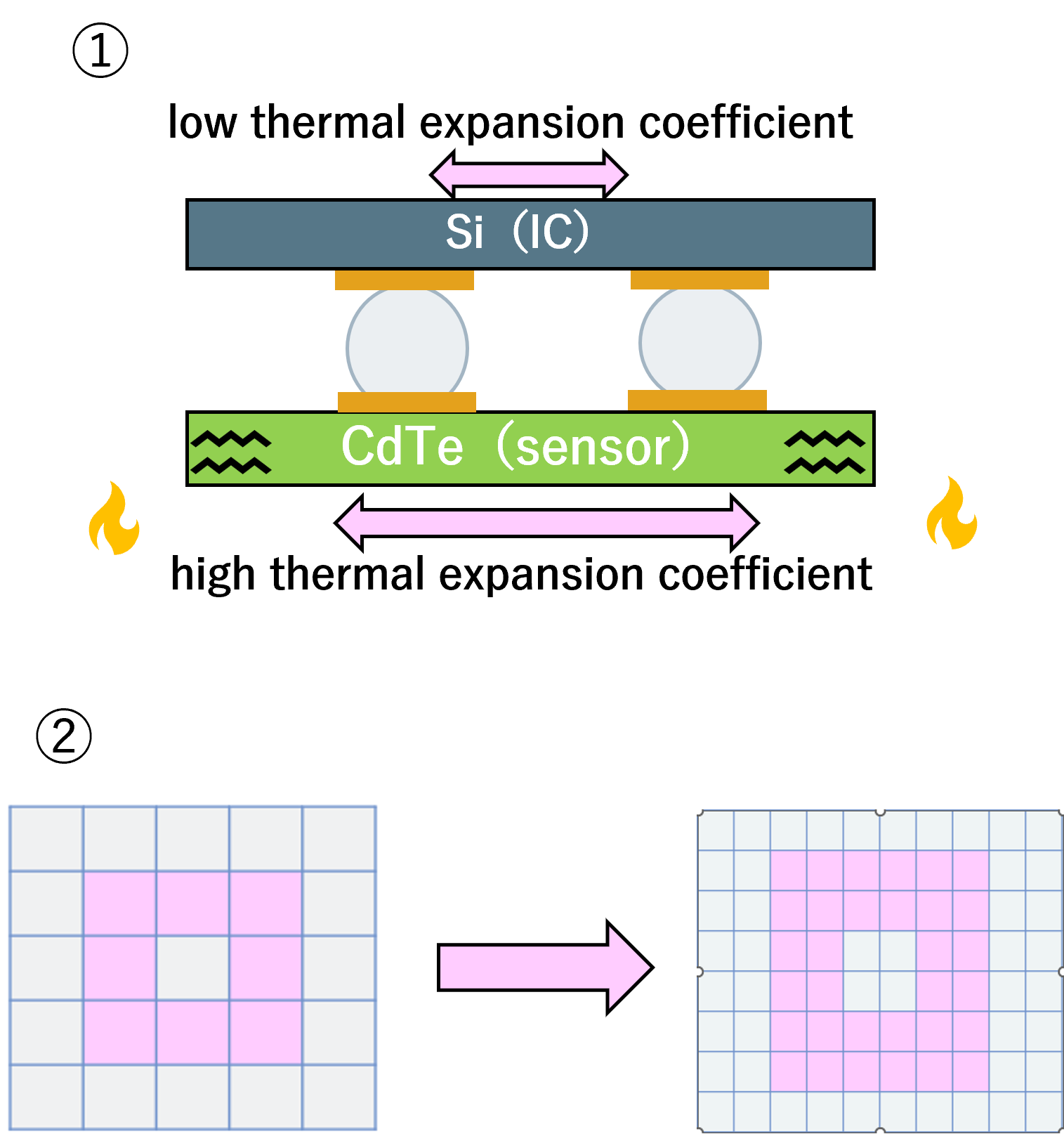

We accept not only Si wafers, but also other types of wafers and substrates like Glass, SiC, InP, GaAs, and so on.

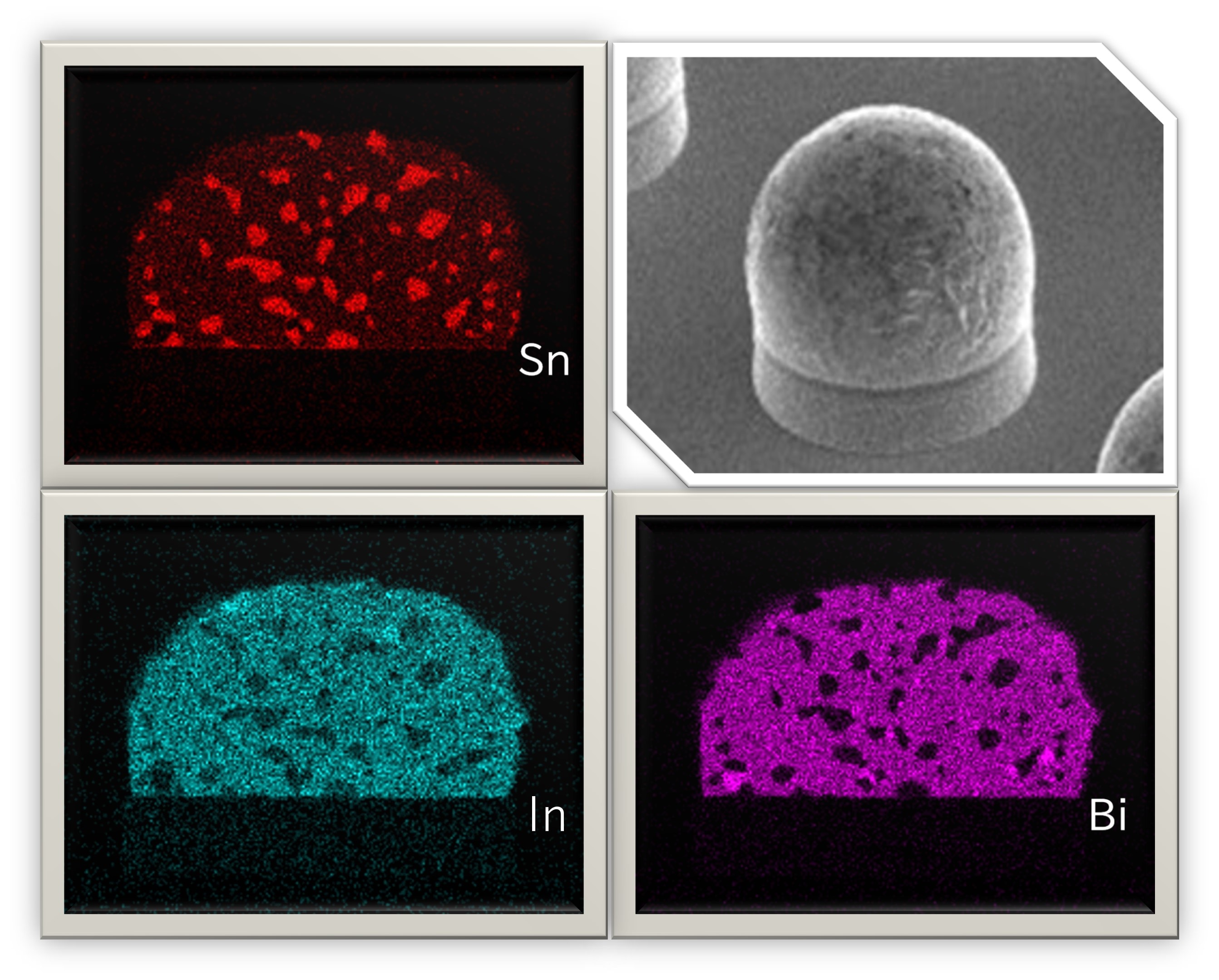

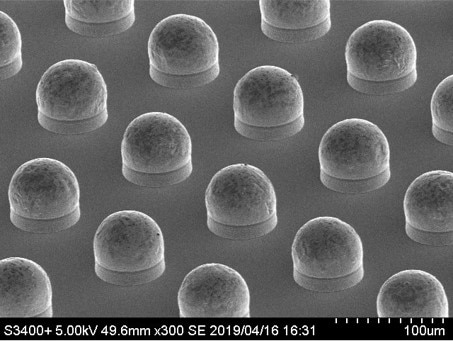

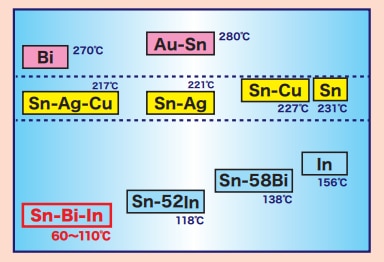

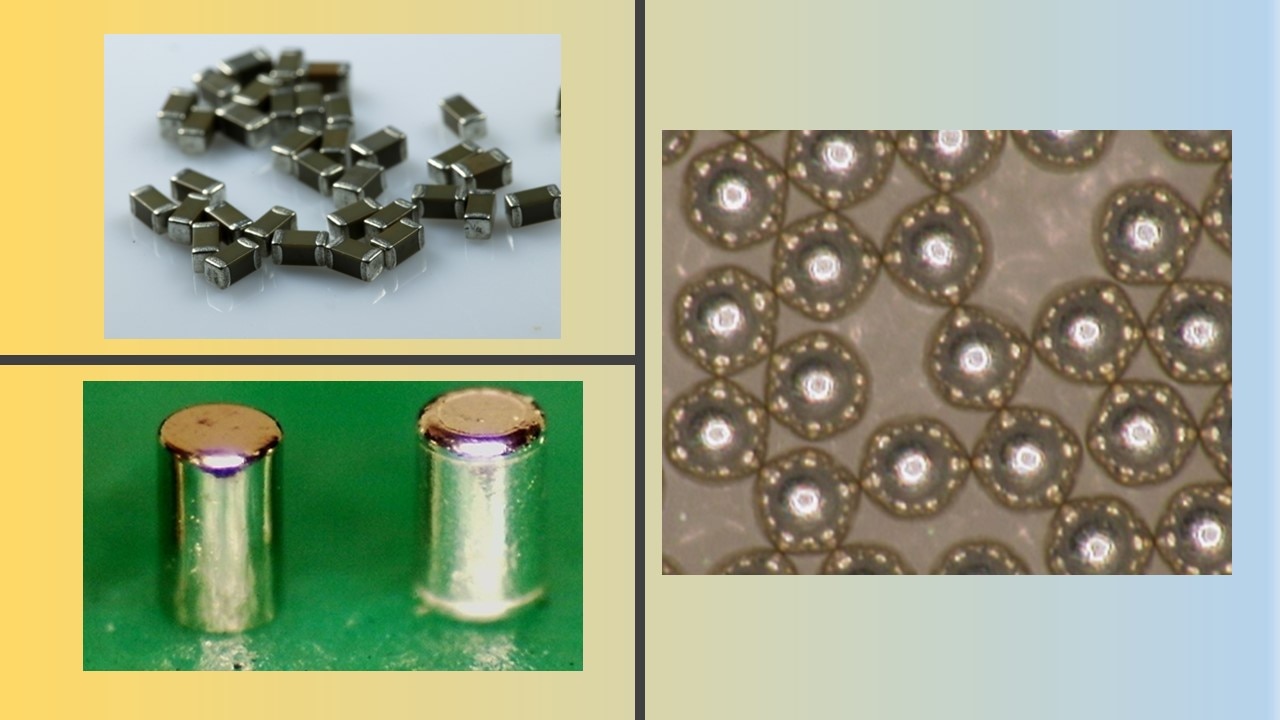

Other than wafers and substrates, we also undertake plating on small components like solder balls, metal powders, and wires.

Shinryo is happy to help our customers from the trial stage,

so we gladly accept even 1 wafer or 1 lot of the components for a trial.

When you do not have wafers for TEG production, we can prepare them ourselves. Please feel free to ask.